Technology

We Evolve Our Ultrasonic Motor.

The feature of SHINSEI CORPORATION’s Ultrasonic Motor: Small size, High torque and Quantity silence ,Low speed and the High holding torque at the time of a stop is the optimal as an actuator of a small system. We are preparing the standard model which held down cost assuming using in a general environment, and the non-magnetic model assuming using in high magnetic field environment.

Compared with an electromagnetic motor, the ultrasonic motor is excellent in the torque weight ratio, and effective also in a miniaturization and weight saving of equipment which needs many motors, such as an arm for robots. In recent years, SHINSEI CORPORATION’s Non-magnetic Ultrasonic motor are attracting interest very much as a motor which can be used in a high magnetic field environment, such as near MRI equipment, and are adopted as an actuator for inclusion of many medical equipment.

Moreover, we succeeded in development of a High Power Eelectrostatic Motor as a new style motor which can rotate at high speed in a vacuum. We are advancing commercial production of this motor now.

What is Ultrasonic Motor?

First type of Ultrasonic Motor:USR-60-4-100

In December 25,1986. The completely new motor which uses neither a Coil nor any Magnet for driving force was put on the market from SHINSEI CORPORATION.

The motor is just an Ultrasonic Motor.

The name of the production is USR-60-4-100. The motor is first type of the present Ultrasonic Motor: USR series.

Ultrasonic Motor rotates using modification when voltage is applied to piezo-electric ceramics.

The name of an ultrasonic motor was named from the frequency of the voltage that is exceeding people’s audible sound region.(Over 20kHz).

Then, the SHINSEI CORPORATION’s Ultrasonic Motor repeated improvement aiming at improvement in functionality and reliability.The concentration of the technology is USR30 series:diameter 30mm and USR60 series:diameter 60mm.

By the result of continuous improvement, USR30 series and USR60 series are adopted in many companies and academic organizations in the world. And because USR30 series and USR60 series have obtained high evaluation, it is considered as a de-facto standard of Ultrasonic Motor.

The lineup of USR30 series and USR60 series are the Standard Model Motor assuming the use in general environment and the Non-Magnetic Model Motor assuming the use in high magnetic field environment.

Structure and Principle of a Ultrasonic Motor:USR series

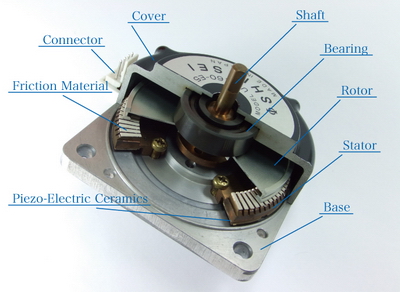

Structure of Ultrasonic Motor

Structure of a Ultrasonic Motor:USR Series

Structure of a Ultrasonic Motor:USR Series

- Stator

- Rotor

- Shaft

- Bearing

Ultrasonic motors: The USR series is roughly divided into four parts.

Structure of a stator part

- Piezo-Electric Ceramics

- Stator metal

- Friction material

Furthermore, the structure of a stator part is the following below;

The Piezo-Electric Ceramics which generate vibration

The Stator metal which makes vibration amplification

The friction material which contacts with a rotor

Feature

- Stable Rotation Performance

- High Holding Power

- High Silence

The structure of Ultrasonic Motor(SHINSEI CORPORATION’s) is a very simple.

The component of a Standard Model Motor and a Non-magnetic Model Motor do not generate electromagnetic waves.

Furthermore, the Non-magnetic Model Motor uses for stator metal and a bearing the material which is not affected at all by the influence of magnetic.

Principle of Ultrasonic Motor

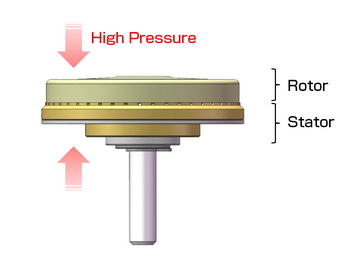

Image of the pressure between Rotor and Stator

-

Summary :

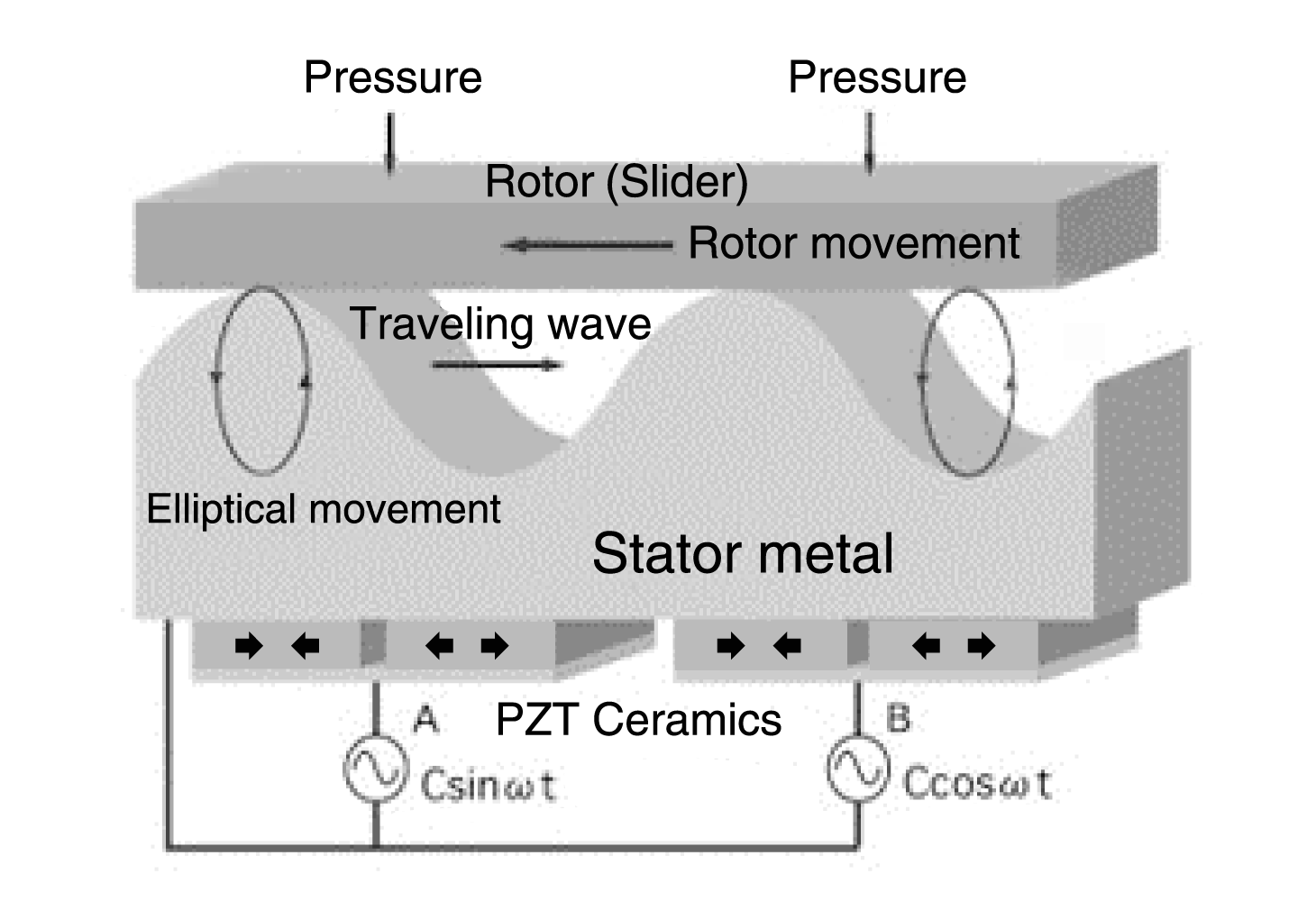

The Ultrasonic Motor uses piezo-electric ceramics for the source of a drive. If voltage is impressed to piezo-electric ceramics, the form of piezo-electric ceramics will change.

The modification is made to amplify and spread with stator metal, and a traveling wave is generated on the surface of stator metal. This wave rotates the rotor which is in contact with the stator.High holding power of Ultrasonic Motor :

High pressure is applied between the rotor and the stator. For this reason, the biggest frictional force at the time of a stop is the holding power of an ultrasonic motor.

Image of the principle of rotation

-

Rotation principle of Ultrasonic Motor :

If voltage is made to apply to piezo-electric ceramics, the shape of piezo-electric ceramics will be changed or distorted. The modification amplifies and spreads with stator metal, and generates a traveling wave on the surface of stator metal.

Here, the stator metal touches the rotor only at each peak of a traveling wave, and each of that peak carries out elliptical movement. A rotor rotates in response to the influence of the elliptical movement.The direction of movement of this ellipse is a direction contrary to the direction which a traveling wave follows. And a rotor rotates in the direction contrary to a traveling wave under the influence.

So, When a traveling wave progresses in the clockwise direction (CW) on the circumference of a stator, each peak of the traveling wave in contact with a rotor carries out elliptical movement in the counterclockwise direction (CCW).

And the rotor in contact with the peak of the wave rotates in the counterclockwise direction (CCW).By controlling the speed and direction of this traveling wave, control of an Ultrasonic Motor is possible.

Feature of Ultrasonic Motor

SHINSEI CORPORATION’s Ultrasonic Motor:USR series is small size, a low speed, and high torque, and is excellent in a response and silence.

Moreover, because it has high holding power at the time of un-applying an electric current, the moving part which does not use reduction gears can be built.

Because the Ultrasonic Motor uses neither the coil nor the magnet, it is not affected about operation of a motor by the influence of magnetic.

And an ultrasonic motor does not generate magnetism during rotation.For this reason, the stable operation in strong magnetic field environments, such as near MRI and superconductivity experiment equipment, is possible.

Now, Ultrasonic Motor is used for the following uses.

| ・Autofocus of a camera | ・Control part of a measuring instrument |

| ・Actuator of the lens mirror of optical equipment | ・Control device of the antenna of an artificial satellite |

| ・Gripper for the robots for industry | ・Automatic controller of a rolling screen |

| ・Conveying machine of parts | ・Attitude control of the measuring instrument near MRI |

| ・Actuator within High Magnetic Field Environment |

Typical Feature

High Torque and Low Speed

The feature of Ultrasonic Motor is high torque at the low speed of 10 – several 100 [rpm].

Neither reduction gears nor a brake is needed, and the direct drive is possible.

It is possible to make the actuator of the backlash 0.

High Holding Power with no electric current

Ultrasonic Motor keeps up high holding power, also in the condition that the power is turned off.

For this reason, a brake and a clutch are unnecessary to an ultrasonic motor.

It is possible to make a lightweight actuator without an electromagnetic brake or a clutch.

High Response and High Controllability

Because the inertia of a rotor is small and the braking effort by friction between rotor stators is large, the response at the time of a stop is excellent.

Because speed control is stepless, and a mechanical time constant is also below 1 [ms], it is very excellent also in controllability.

For this reason, highly accurate speed control and position control are possible.

Usable in a High Magnetic Field and Not generate Electromagnetic Waves.

Since neither winding nor a magnet nor a coil is used, an ultrasonic motor does not generate electromagnetic waves.

Specially, since a nonmagnetic type ultrasonic motor does not use a magnetic material at all, it operates without being affected in a high magnetic field environment by the influence of magnetic.

Small, Thin and Lightweight

Compared with the Electromagnetism Motor of torque of the same degreea, Ultrasonic Motor is Small, Thin, and Weight is several percent.

By using as an articulated robot’s arm or an actuator of a leg, weight of each joint can be made light.

Improvement in the response of a robot or the whole system and improvement in weight capacity are expectable by adopting Ultrasonic Motor.

High Silence

Because vibration used for a drive is the frequency of a non-auditory area, its operation sound is very quiet.

Moreover, it is possible to avoid generating of the noise of a drive by not using a gear.